Features

Light Fading resistance

Last technology has achieve industry higher fading resistance caused by light UV A and UV B spectrum. Suppressing silver-halide, pigment and dye inkjets by large margin. Rated for 200 years of unprotected indoor exposure under 500 lux 10h/day bright room conditions.

Learn More

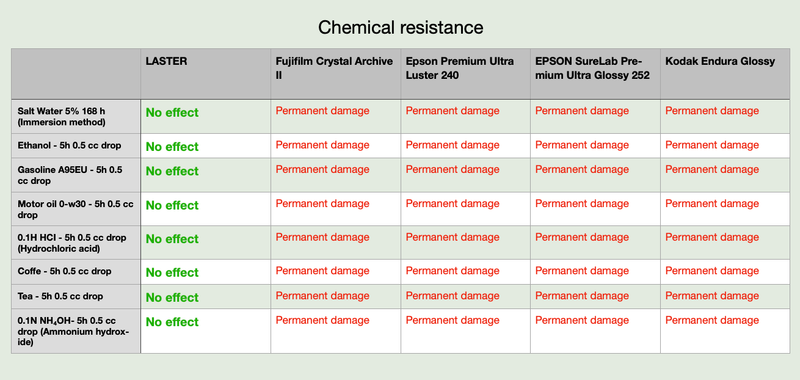

Chemical resistance

Our prints are virtually indestructible by any of the most common environments related deterioration factors, such high humidity (water damage), Ozone and other gases in the atmosphere, high level of acids and many more. No special storage condition is required.

Fully eliminated Gloss differential (bronzing effect)

As our technology is bade on direct infusion of the dyes in to the material it is not affected by inevitable problem of fine art pigment inkjet printers of Gloss differential in heavy ink covered areas. This also allows as to use ultra glossy surfaces with mirror like finish. Picture show Top - Pigment ink on glossy paper, Bottom LASSTER Ultra glossy

Very wide color space with bright saturated colors

LASSTER combines successfully all advantages of exiting finer art printing technologies without their negatives sides. Bright and pop-up colors of dye inkjet, large color space of pigment inkjet all in one. Eliminate the problems of chemical light sensitive process as dull reds and low maximum density and many more.

Non tearable ultra durable polymer

We have manage to eliminating aging deterioration risk by removing all natural based materials such cellulose, cotton, silver etc. highly vulnerable under environment condition, by using flexible monolith polymer material virtually non-aging and non-tearable.